Modular Control Robotics System (MCRS)

ModnyCo successfully developed an advanced robotic system, featuring precise control mechanisms with stepper, servo and DC motors, efficient LED management, and a master-slave PCB configuration for optimized communication. We implemented dynamic motor control, adjustable speed profiles, and advanced LED brightness models, supported by robust communication protocols and a custom, user-friendly joystick interface with OTA firmware update capabilities. This project exemplifies our commitment to innovative, efficient, and user-centric design in sophisticated robotic systems.

- Engineered a sophisticated robotic system equipped with stepper, servo and DC motors and advanced LED management systems.

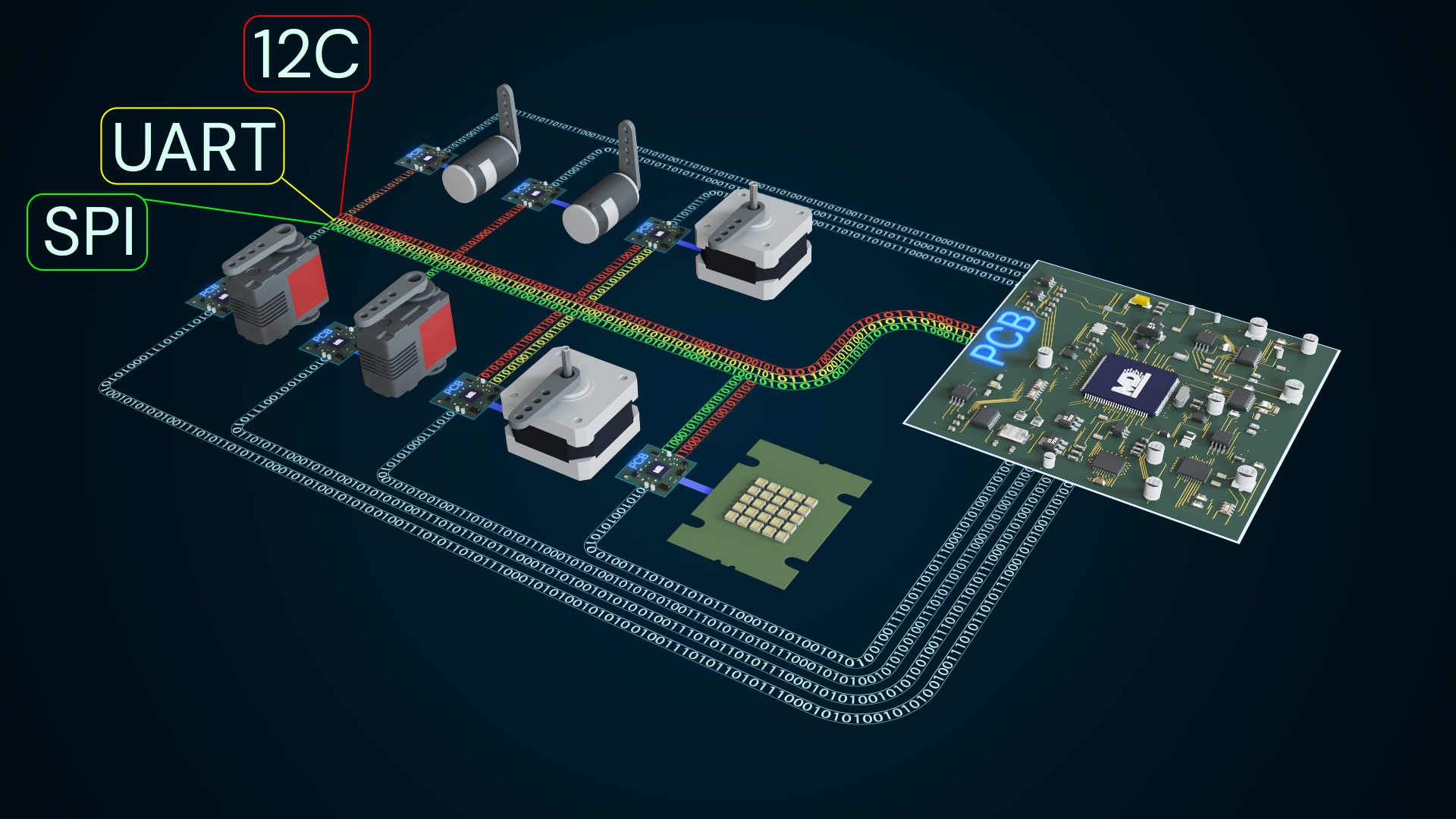

- Implemented a strategic PCB layout with a central master PCB and multiple slave PCBs, optimizing digital communication and reducing analogue signal reliance.

- Centralized control with a Microchip SAM series microcontroller on the main PCB, while maintaining minimalistic, microcontroller-free slave PCBs.

- Developed dynamic control systems for stepper motors in embedded C, enabling real-time speed and direction adjustments with automatic ramp-up/down capabilities.

- Incorporated fully dynamic adjustable speed profiles and step resolution, facilitating smooth operational transitions and enhanced user control.

- Utilized differential communication protocols on standard I2C and RS232 protocols, ensuring robust and distortion-free data transfer.

- Designed a bespoke joystick PCB with integrated calibration processes.

- Implemented over-the-air firmware updates, enhancing user interaction and system longevity.

In an innovative endeavour at ModnyCo, we embarked on the development of a highly sophisticated robotic system, integrating a suite of complex technologies and components. The heart of this project was the creation of a robotic system powered by a range of stepper, servo and DC motors, coupled with a versatile LED management system for both high and low-current LEDs.

The essence of the design philosophy involved a strategic division of the system into multiple slave, and a single central master PCBs. This division was crucial for optimizing communication within the system, allowing us to shift from high-power analogue signals to more efficient low-power digital signals throughout the mechanical assembly, enhancing overall performance, reliability and EMI footprint.

A distinctive feature of our approach was the minimalistic design of the slave PCBs, which operated without any embedded microcontrollers, in contrast to the master PCB that was equipped with a sophisticated Microchip SAM series microcontroller. This setup effectively centralized control and processing power.

In terms of control dynamics, we employed embedded C to craft a nuanced control system for the stepper motors. This system was not only capable of performing automatic ramp-up and down but also maintained consistent speed, adapting in real time to changes in motor speed or direction as commanded by the user. This level of dynamic control allowed for seamless transitions and precise movement, crucial for the robotic system's efficiency and accuracy.

Further enhancing the system's adaptability, we incorporated fully adjustable speed profile settings with the capability for dynamic step resolution adjustment. This feature meant that users could modify speed and step resolution on the fly, with the system responding smoothly to these transitions.

A key challenge in this project was the LED brightness control. We developed calibrated LED brightness models that employed non-linear control of the LED supply current. This sophisticated approach ensured a linear and reliable luminosity control, crucial for the system's operational consistency.

Communication within the system was another area we focused on intensively. By implementing differential communication protocols, the slave PCBs could share a communication line with the main PCB without any loss of signal quality or integrity. This system used multiple communication protocols, including I2C, RS232, and EEPROM for data retention, ensuring a robust and versatile communication network.

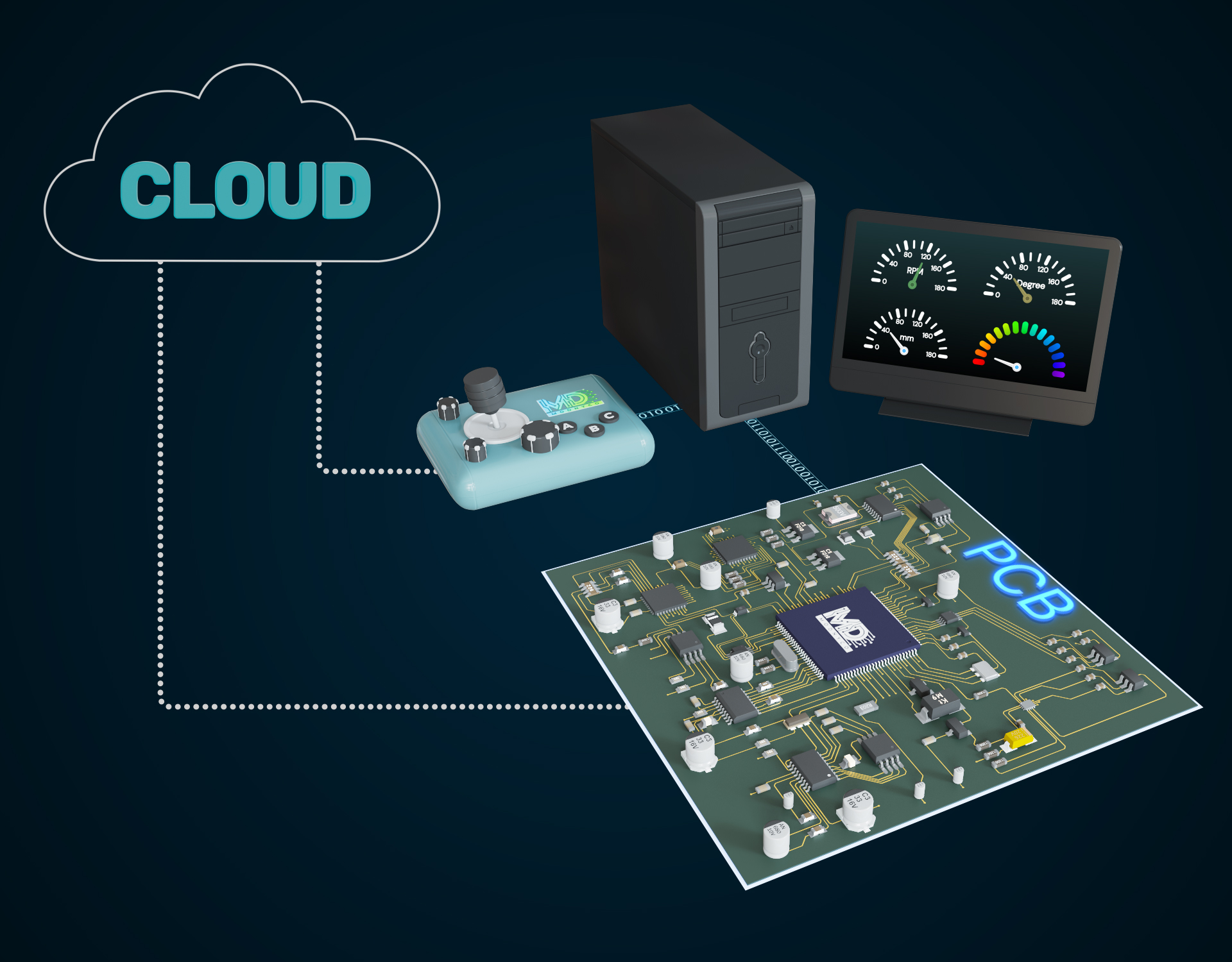

Additionally, we developed a bespoke communication protocol through a serial port, enabling high-level commands from a connected PC to be interpreted and executed by the microcontroller on the main PCB. This protocol employed both synchronous and asynchronous response techniques, allowing for confirmation of command execution and completion, enhancing the system's reliability and user feedback.

An intriguing aspect of this project was the design of a custom joystick PCB, complete with multi-axis joystick and controller knobs, as well as keypad inputs. The joystick, powered by an AVR microcontroller and connected to a PC via USB, was recognized as an HCI device on Windows machines, ensuring compatibility and reliability across different devices. We also implemented a calibration process for the joystick and knobs post-production to standardize performance despite manufacturing variances.

Finally, to ensure the system's longevity and adaptability, we integrated an over-the-air (OTA) firmware update feature. This allowed for both the joystick and main PCB firmware to be updated remotely, ensuring that the system remained at the cutting edge of technological advancements.

This project at ModnyCo stands as a testament to our ability to integrate diverse technologies and components into a cohesive, efficient, and highly advanced robotic system.

Schedule a Consultation

Connect with our team to transform your complex concepts into market-ready electronic solutions.