Our Projects

Modnyco operates at the cutting edge of several industry sectors, harnessing our specialized skills and innovative mindset to drive progress and transformation.

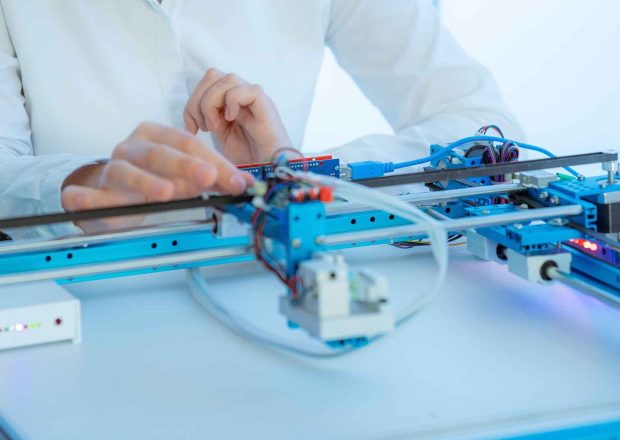

Modnyco achieved a breakthrough in robotics with a state-of-the-art system, boasting precise control, efficient LED management, and advanced communication for user-friendly operation.

Modnyco innovatively integrates infrared and ultraviolet light for precise material analysis, featuring automated positioning and advanced machine learning, ensuring accurate testing and calibration.

Modnyco achieved precision in tinted lens analysis using machine learning algorithms. Controlled wavelengths, trained classifiers, and dynamic color definition showcased innovative optical solutions.

Modnyco leads a groundbreaking initiative, creating a pneumatic system on soft surfaces with Microchip SAM controllers, ensuring precision and data analysis.

Modnyco collaborated with a firmware development team to enhance STM microcontroller firmware, optimizing code, adding features, and ensuring compliance.

Modnyco rigorously tested lens meters, establishing benchmarks and evaluating precision through repetitive, advanced analyses for improvements.

Modnyco developed a smartphone technology to measure eye refractive states, using machine learning to detect conditions and filed a patent, advancing eye diagnostics.

Modnyco developed a Smart Gas Oven integrating AI-driven automation with real-time sensor data, powered by ARM Cortex and STM microcontrollers, offering cloud-based data logging and continuous improvement through OTA updates.

Modnyco developed an advanced smart fridge with dynamic inventory tracking for retail beverage dispensing, integrating robust sensor technology with cloud-based analytics and inventory management.

Modnyco achieved success by creating a robust API for embedded Linux on a multi-core ARM Cortex microprocessor, enabling high-speed data processing for multiple cameras with diverse specifications.

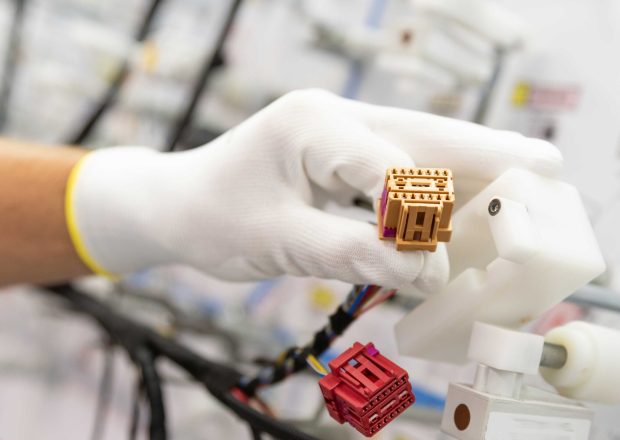

Modnyco developed a PCB testing system with Microchip AVR, streamlining cable assembly with user-friendly features, LEDs, and efficient troubleshooting.

Modnyco created a C# Windows app using image processing to streamline mechanical assembly calibration, enhancing precision and reducing costs.

Modnyco developed test software, subjecting a motorized assembly to 25k cycles, gauging durability. Results inform product manual, highlighting data-driven evaluations for longevity.

Modnyco created a Windows-PC diagnostic software for efficient assembly line operations, seamlessly integrating with microcontrollers to detect errors visually.

Modnyco crafted Windows software for precise calibration of custom 3D joysticks in robotic systems. It guides operators through tasks, ensuring optimal performance by processing raw data and storing settings.

Schedule a Consultation

Connect with our team to transform your complex concepts into market-ready electronic solutions.