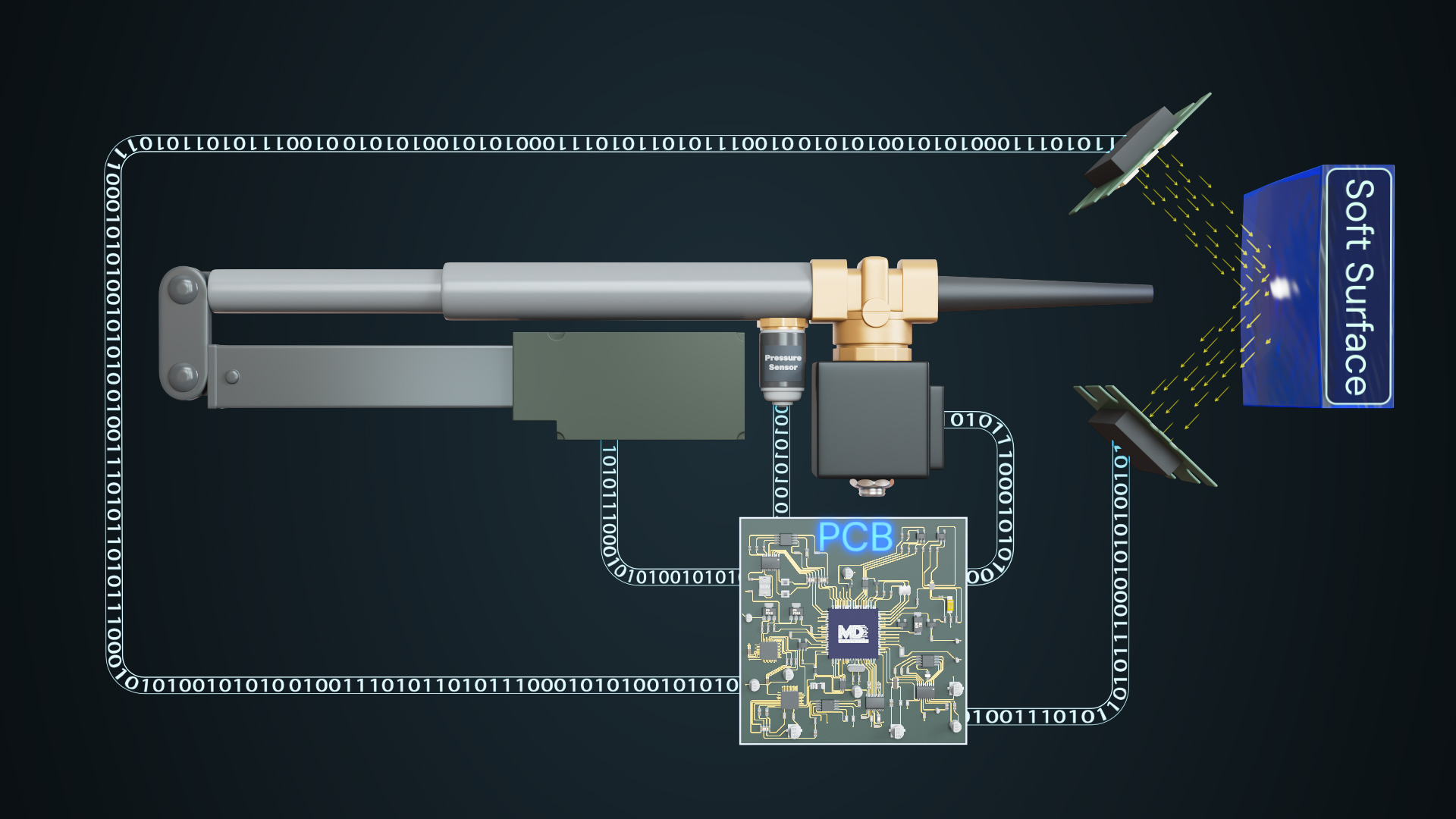

Soft-Surface Pneumatic Analyser

ModnyCo led an innovative project to design a pneumatic system for controlling air pressure on a soft surface, integrating pneumatic components, servo motors, and infrared sensors, all managed by high-capacity Microchip SAM microcontrollers and utilizing efficient I2C and SPI communication protocols for precise operation and data analysis.

- Designed a pneumatic system to precisely control air pressure and flow on a soft surface.

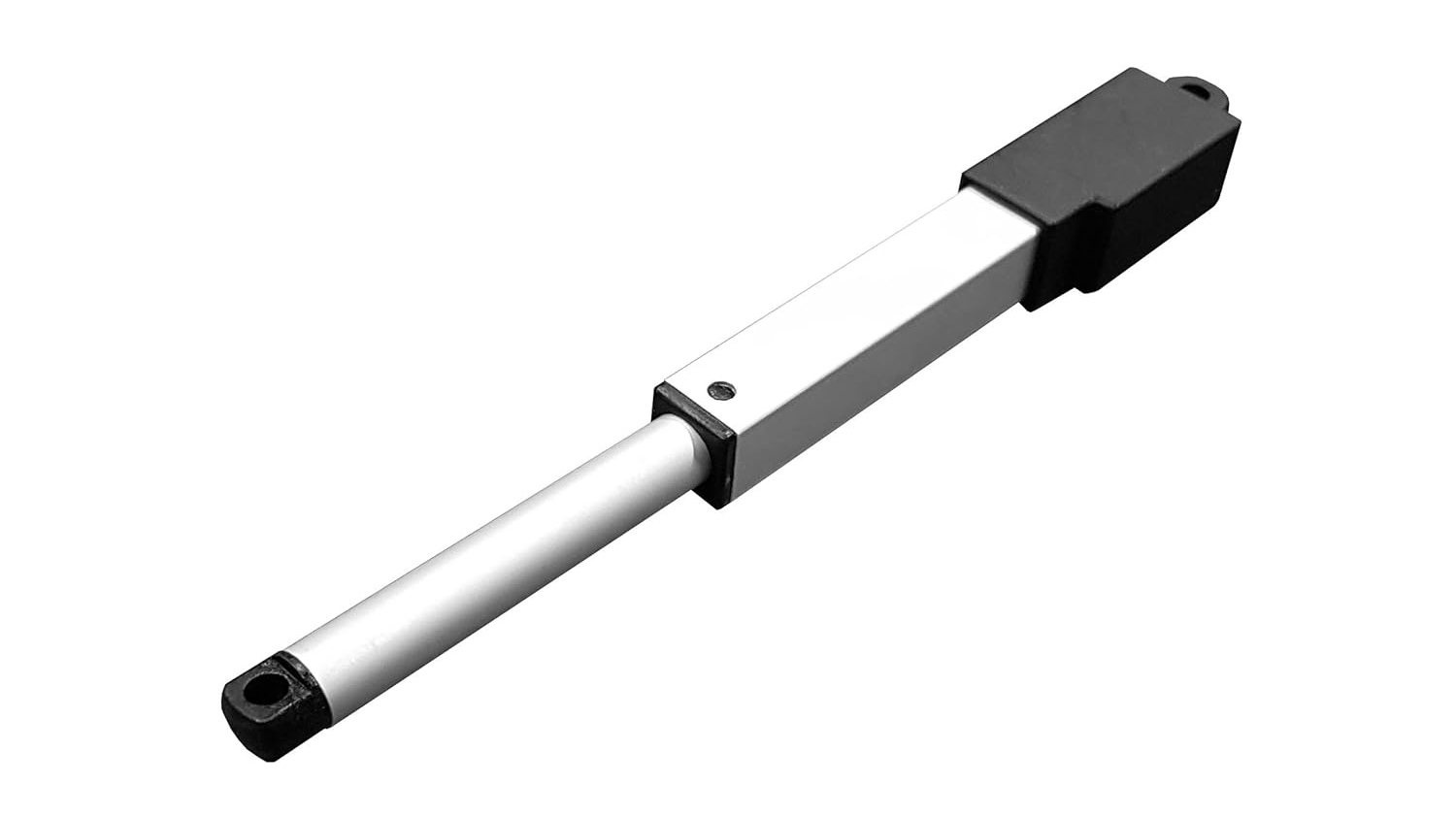

- Integrated pneumatic valves, pressure sensors, and servo motors for airflow pressurization.

- Employed infrared sensor arrays to analyse the soft surface's response to airflow.

- Chose Microchip SAM microcontrollers for their high onboard RAM, facilitating data acquisition and analysis.

- Utilized I2C and SPI communication protocols for efficient sensor data transmission.

ModnyCo undertook an innovative project that showcased our proficiency in pneumatic systems and sensor integration, focusing on controlling air prussor and flow to interact with soft surfaces. This project was a blend of electronics engineering and data analysis, highlighting our ability to develop complex, integrated systems.

The project's primary objective was to design a pneumatic system capable of precisely controlling the pressure and flow of air directed at a soft surface. To achieve this, we employed a combination of pneumatic valves, pressure sensors, and servo motors. The servo motors were integral to the system, functioning to control the mechanical assembly that pressurized the air. This precise control mechanism allowed us to manipulate the air pressure with great accuracy.

Upon the release of the directed airflow onto the soft surface, our focus shifted to analysing the surface's response. For this, we utilized an array of infrared transmitters and receivers. The sensor array was critical in assessing how the soft material reacted to the airflow, providing vital data on the interaction between the air and the surface.

The Microchip SAM microcontroller was selected specifically for its high onboard RAM, which was essential for seamless data acquisition and analysis. This choice underscored our commitment to using the most suitable technology for optimal system performance.

The communication between sensors in this system was facilitated through I2C and SPI communication protocols. These protocols were chosen for their reliability and efficiency, ensuring that the sensor data was transmitted swiftly and accurately for real-time analysis.

This project stands as a testament to ModnyCo’s ability to create sophisticated systems that integrate mechanical and electronic components seamlessly. By leveraging our expertise in microcontroller technology and sensor communication, we developed a pneumatic system that not only met but exceeded the project's requirements, demonstrating our capability in advanced system design and implementation.

Schedule a Consultation

Connect with our team to transform your complex concepts into market-ready electronic solutions.