UV Classifier

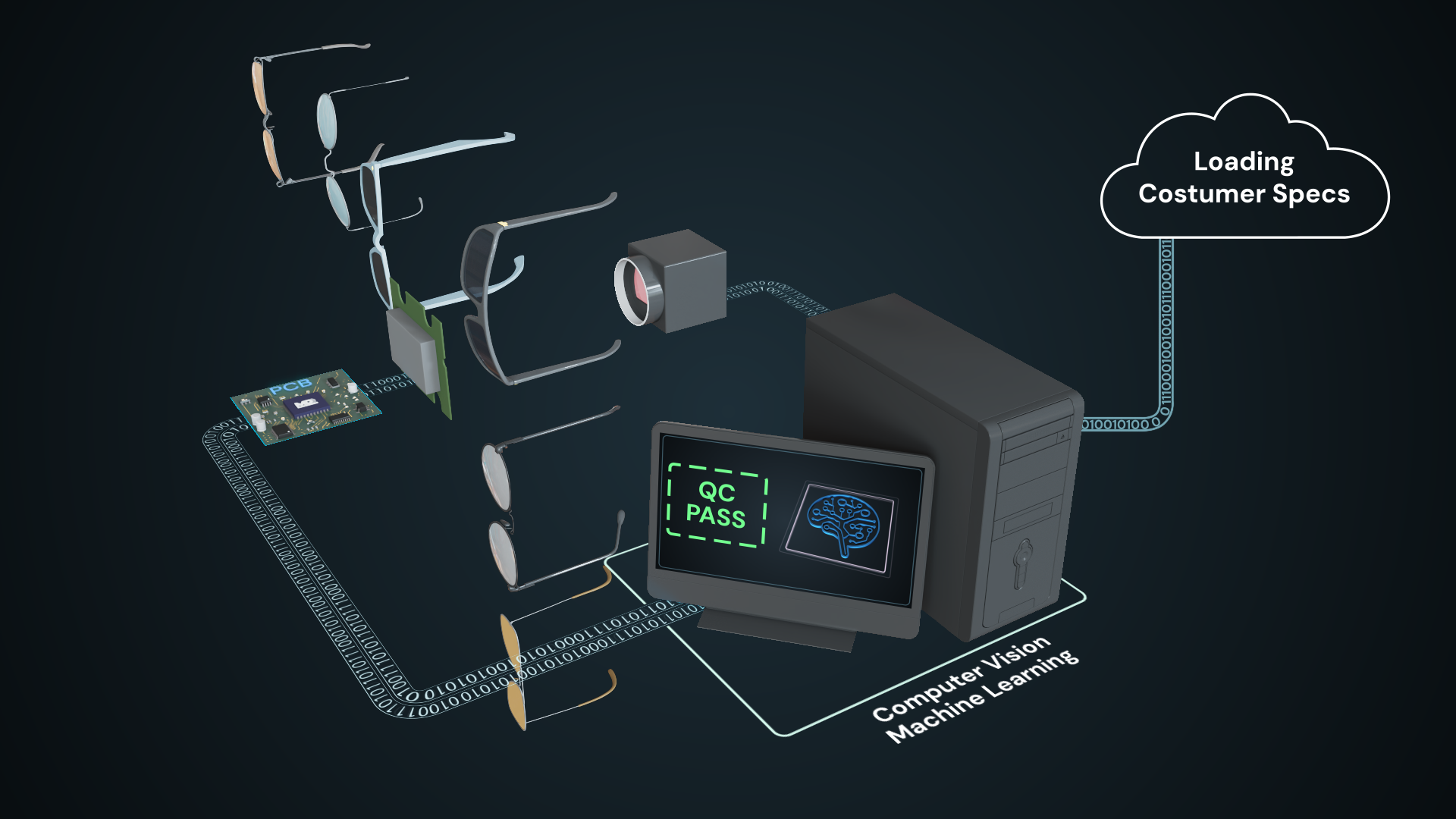

ModnyCo developed a cutting-edge system for lens material analysis using ultraviolet and Deep Blue light, incorporating precise emission control and machine learning for accurate testing and calibration. This project showcases our adeptness in blending sophisticated hardware with advanced machine learning algorithms, delivering a smart, reliable solutions.

-

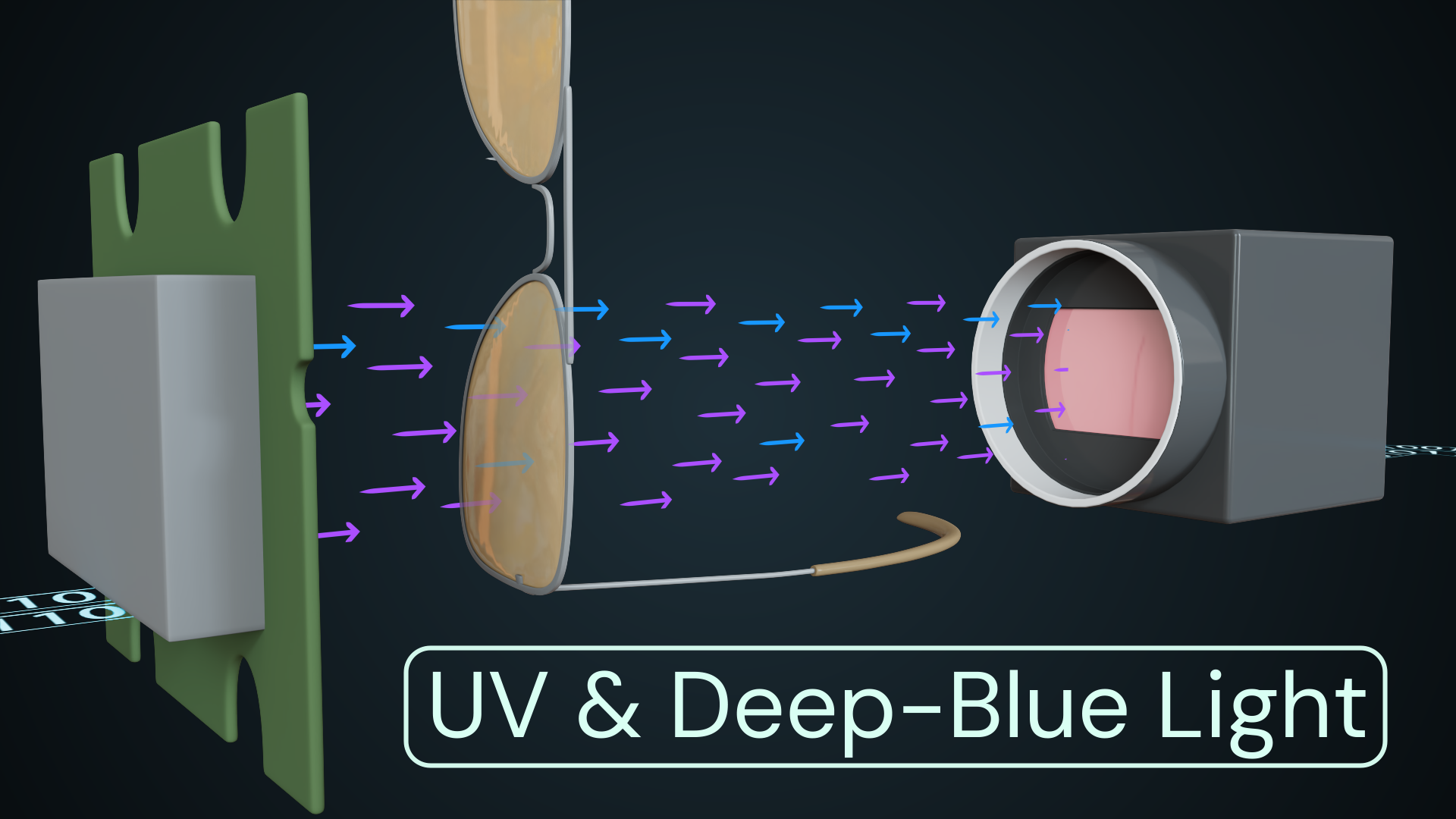

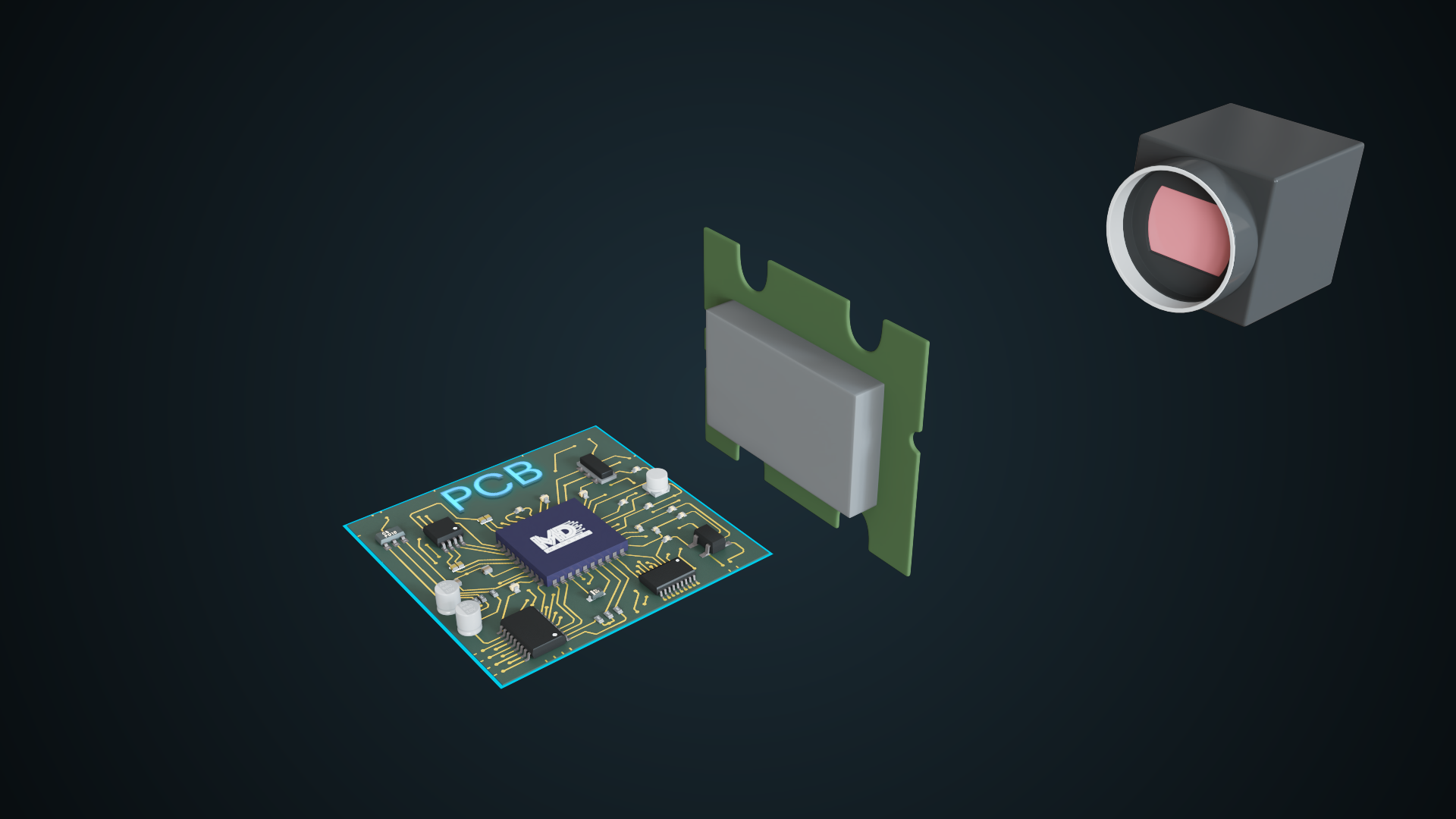

Designed a system for emitting and measuring ultraviolet and Deep Blue wavelengths to test lens transmission and absorption. - Developed a light-emitting PCB with a Microchip AVR microcontroller and current adjustment circuitry for precise control of light emissions.

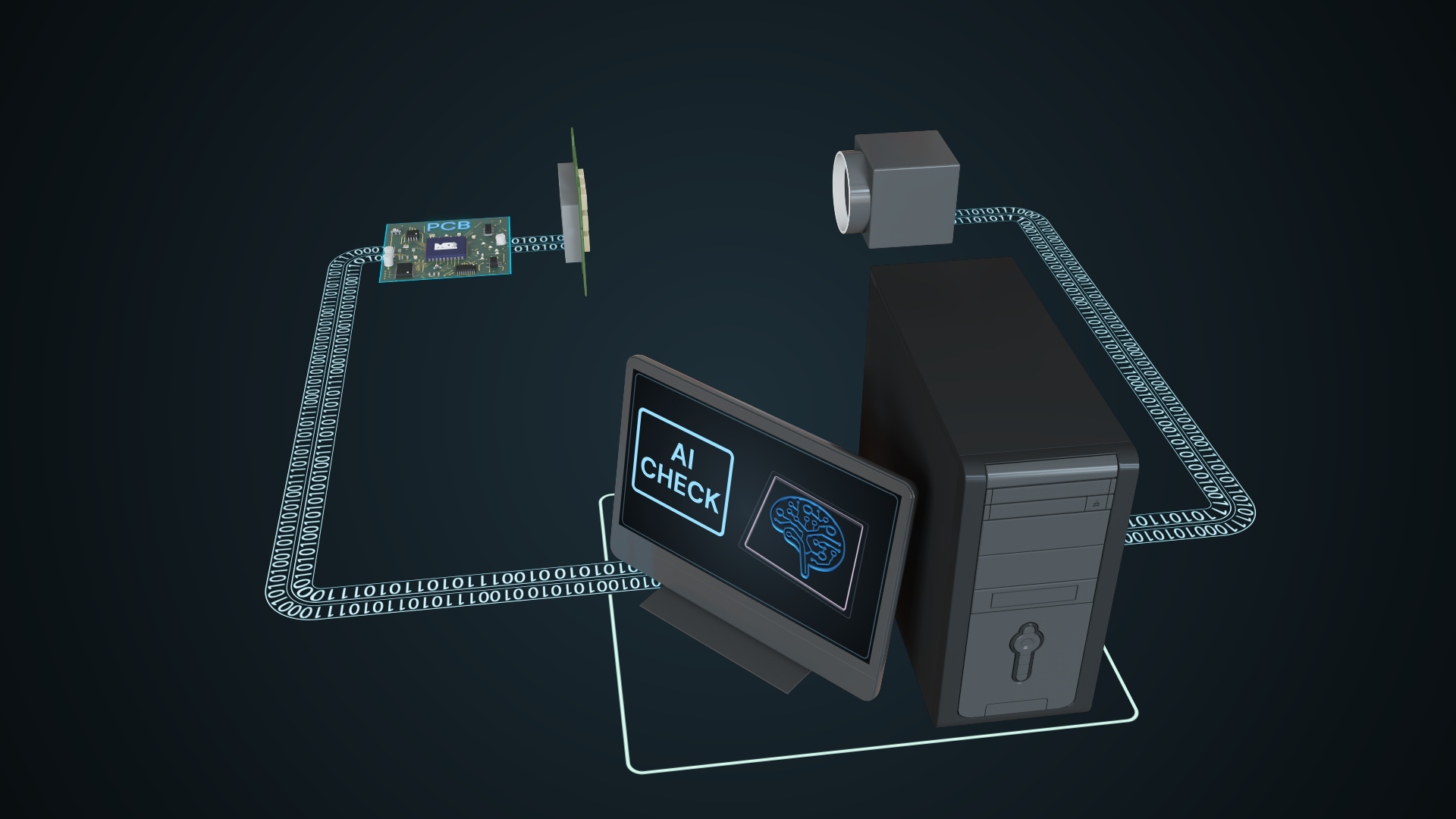

- Utilized embedded C for microcontroller programming, enabling full control over the lighting components from a Windows PC application.

- Established a bespoke communication protocol for microcontroller-PC interaction via serial port.

- Implemented a C# API for seamless Windows application integration, complete with error logging and handling.

- Employed machine learning for calibrating the ultraviolet and Deep Blue LEDs brightness to account for device variability and prevent acquisition module saturation.

- Utilized machine learning techniques to optimize the pass/fail classification based on standard criteria.

ModnyCo embarked on a project that epitomizes our capability in integrating advanced technology with precision engineering. This project involved designing a system capable of emitting specific ultraviolet and Deep Blue wavelengths to assess the transmission and absorption factors of various materials.

The core of the system was a light-emitting PCB, equipped with a Microchip AVR microcontroller and finely-tuned current adjustment circuitry. This setup allowed for precise control over the ultraviolet and Deep Blue emissions.

Central to the system's functionality was the AVR microcontroller, programmed in embedded C. It provided comprehensive control over the lighting, interfacing seamlessly with a Windows PC-based application. This application didn't just control the system; it also managed data acquisition, facilitated by a custom-designed communication protocol over a serial port.

An API, developed in C#, was implemented to enable smooth communication between the Windows application and the system. This included robust error logging and handling mechanisms, ensuring reliable and consistent operation.

Addressing the challenge of production variability, especially in the performance of the ultraviolet and Deep Blue LEDs and the sensitivity of the acquisition module, we employed machine learning algorithms. These algorithms were integral to a calibration mechanism, which adjusted the brightness of each LED to prevent saturation in the acquisition module. Scheduled to repeat monthly, this calibration process also accounted for potential LED performance degradation over time.

Finally, we utilized machine learning techniques to optimize the lens testing process. Based on light emission tests, it provided a classification of 'pass' or 'fail' according to customer order criteria, showcasing our proficiency in blending mechanical engineering, software development, and AI quality control processes.

This project is a testament to ModnyCo's commitment to delivering technologically advanced, solution-oriented systems.

Schedule a Consultation

Connect with our team to transform your complex concepts into market-ready electronic solutions.