Cable Harnessing Evaluation

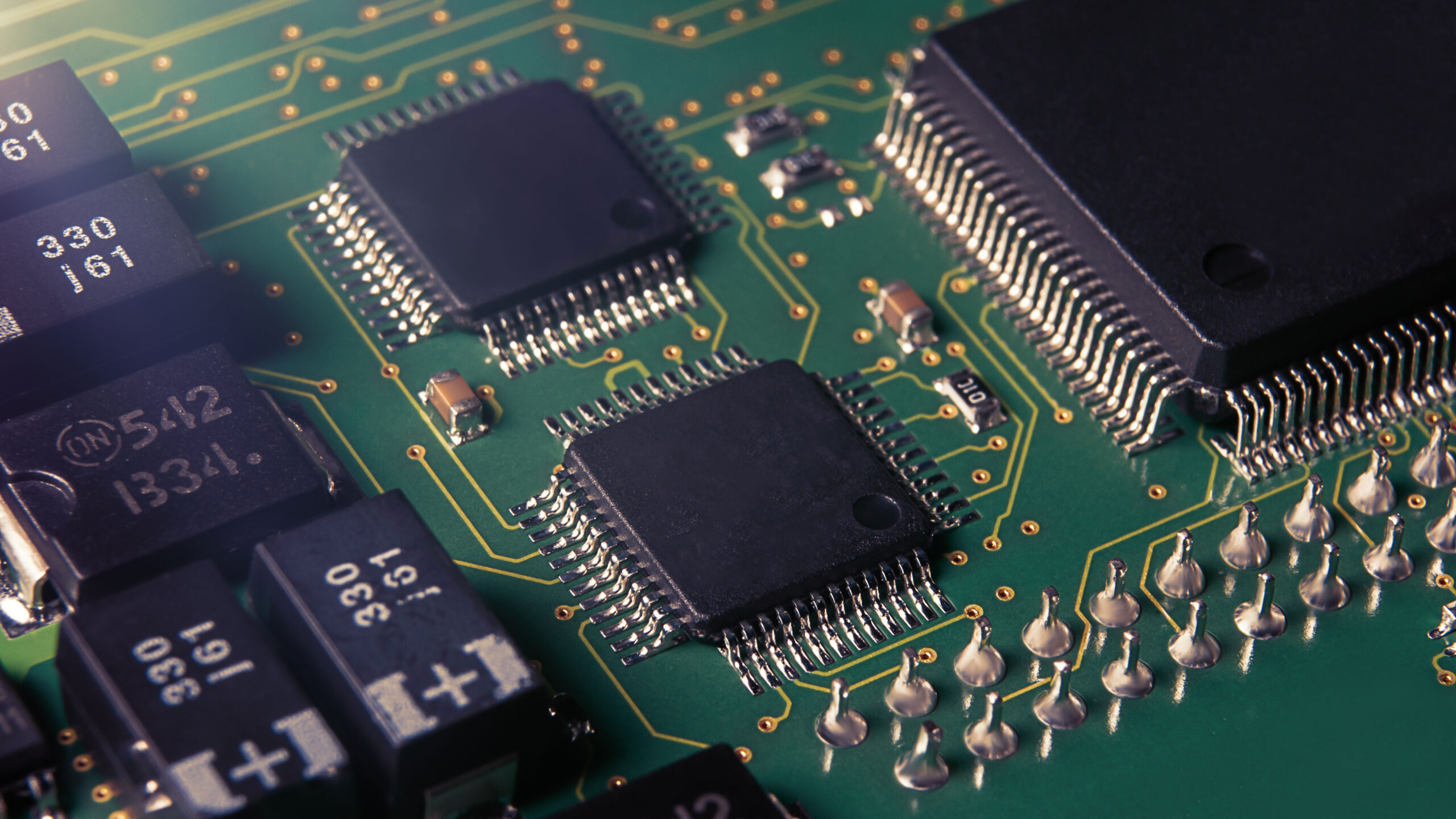

Modnyco designed an innovative PCB testing system for custom cables, featuring a Microchip AVR Microcontroller and a user-friendly interface. This system simplified the assembly process by allowing operators to easily test cables against a reference standard, with immediate pass/fail feedback via LED indicators. Additionally, it offered detailed fault logs through a PC connection for efficient troubleshooting and potential cable reuse, significantly enhancing assembly efficiency and reducing waste.

- Developed a PCB for testing custom cables used in a device for shorts and open circuits.

- Integrated a Microchip AVR Microcontroller connected to various connectors for comprehensive cable testing.

- Simplified testing process: operators use a reference cable to set the standard pinout, then test other cables against it.

- Immediate feedback system with a green LED for pass and red LED for fail, ensuring only functional cables are used in assembly.

- Included a feature to provide detailed fault logs to a PC via serial port upon cable failure, identifying specific faulty pins and fault locations.

- Enhanced troubleshooting efficiency and enabled potential reuse of cables, contributing to resource-saving and waste reduction.

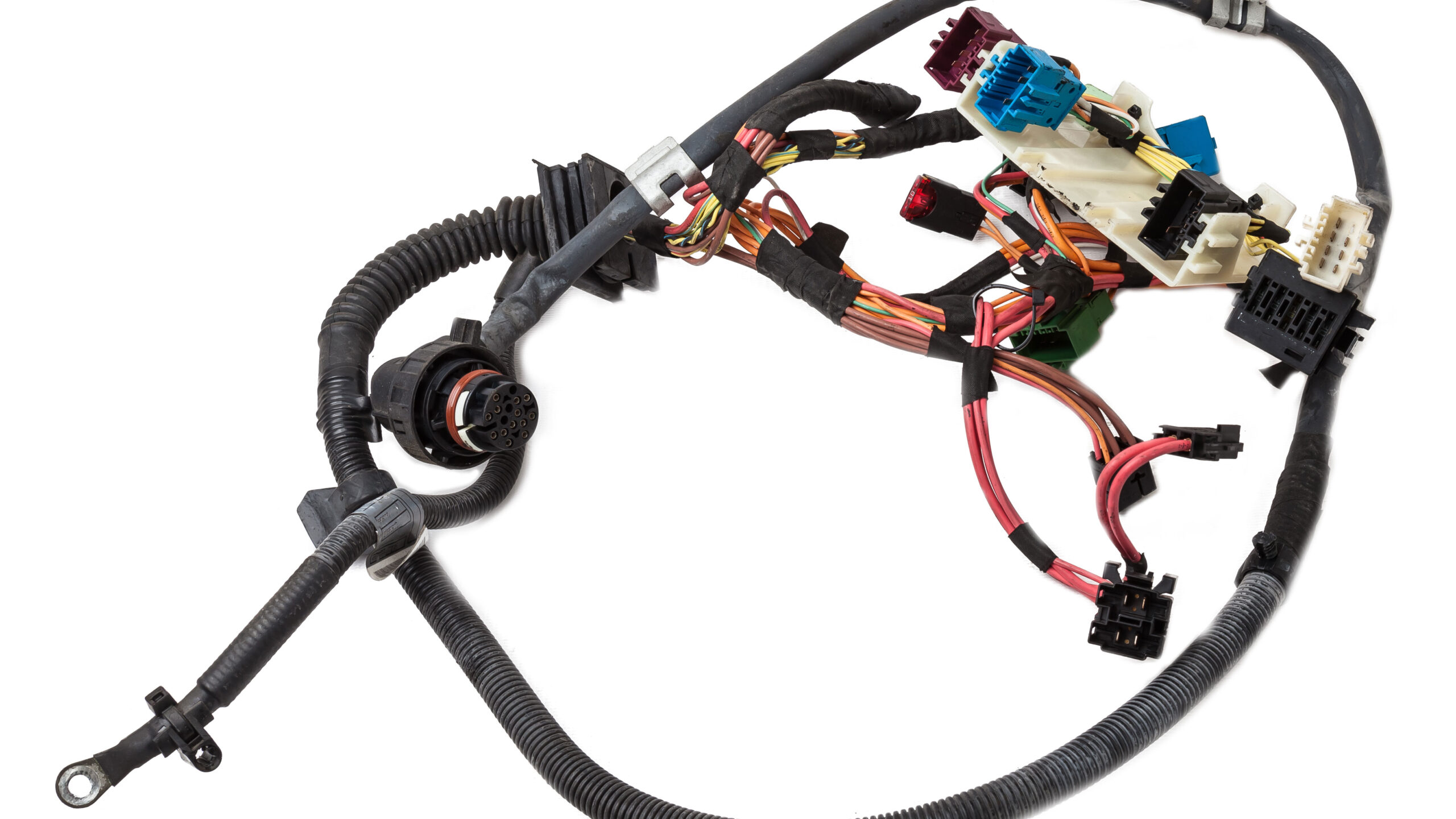

Modnyco was approached by a client facing a unique challenge in their production process. They needed an efficient method to test custom cables used in their devices for short and open circuits before assembly. Our solution was to design a specialized PCB that would revolutionize their assembly process.

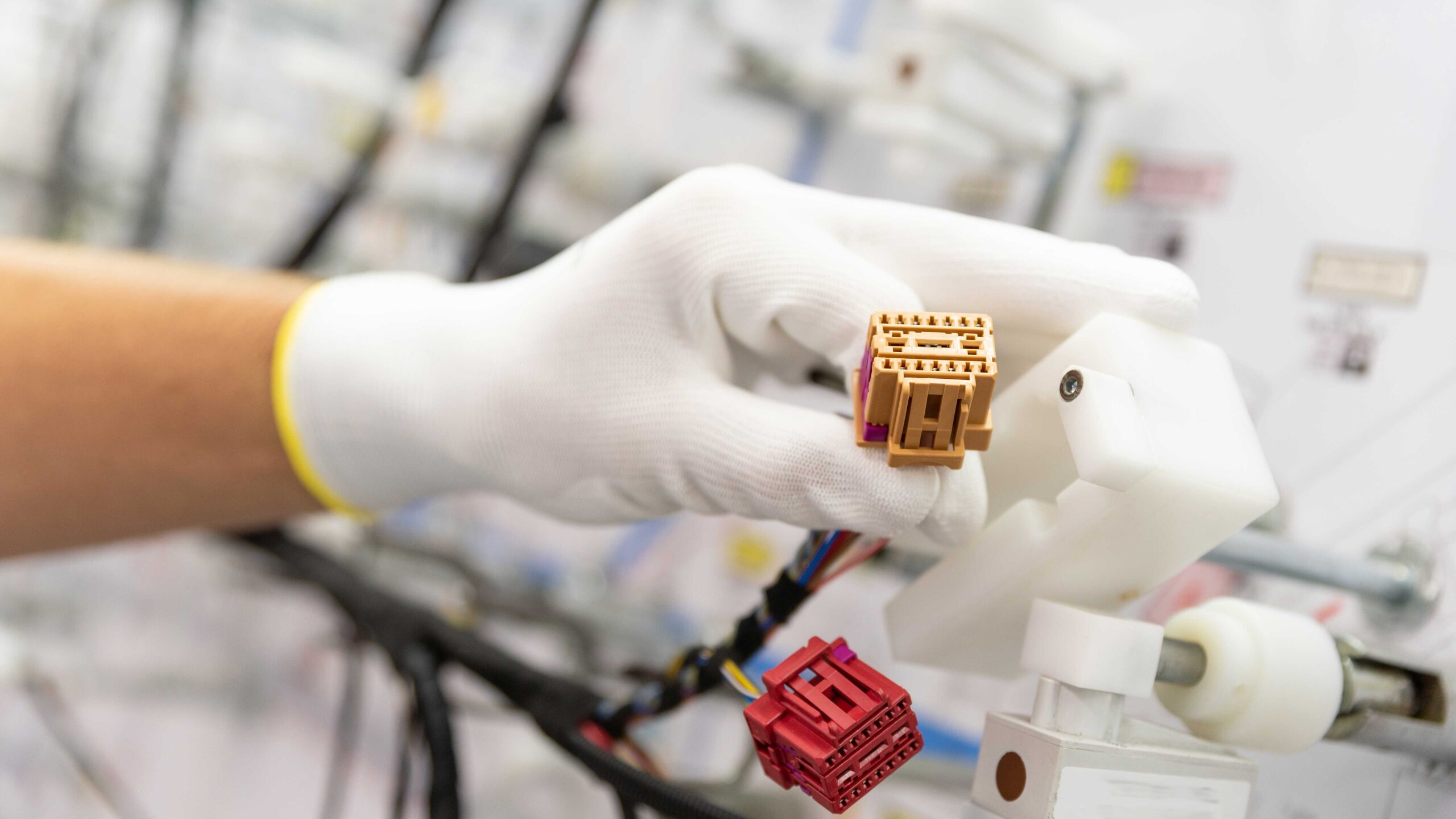

The design was a PCB that housed all the different header types found in the client's device. At the core of this system, we integrated a Microchip AVR Microcontroller, meticulously wired to these connectors to represent all possible cable connections in the device's design. This setup was crucial in ensuring that every potential cable configuration could be tested accurately.

The process for the assembly operator was simplified to its essence. It began with using a reference cable – one whose quality and functionality had been previously verified and approved. The operator would connect this cable to the board and press a push button. This action triggered the microcontroller to memorize the exact pinout of the cable, establishing a standard against which all other cables would be tested. The system was designed to give immediate feedback: a green LED would light up to indicate a Pass (meaning the cable was free from shorts or open circuits), while a red LED would signal a Fail. This straightforward, color-coded feedback system made it incredibly easy for the assembly operators to identify any faulty cables.

When a cable failed the test, our system provided a detailed fault log to a connected PC via a serial port. This log pinpointed the specific faulty pins and the exact location of the short or open circuit, enabling efficient rectification and potential reuse of the cable. This feature not only streamlined the troubleshooting process but also contributed to resource-saving and waste reduction in the manufacturing workflow.

The impact of this device on the client's assembly process was substantial. Prior to its introduction, any cable malfunction detected after assembly necessitated a time-consuming and costly process of partial or full disassembly, repair, and reassembly.

Our solution significantly reduced this complexity, streamlining the assembly process by ensuring that only fully functional cables were used. This not only saved time and resources but also enhanced the overall reliability of the final product.

This project was a perfect example of Modnyco's ability to deliver practical, innovative solutions tailored to specific production challenges. By understanding the client's needs and employing our expertise in PCB design and microcontroller programming, we were able to create a tool that brought efficiency and reliability to their assembly line.

Schedule a Consultation

Connect with our team to transform your complex concepts into market-ready electronic solutions.